Pressure Reducing Valves

Manufacturing PRV & Strainers In Stainless Steel Body

Pressure Reducing Valves

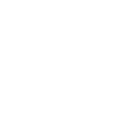

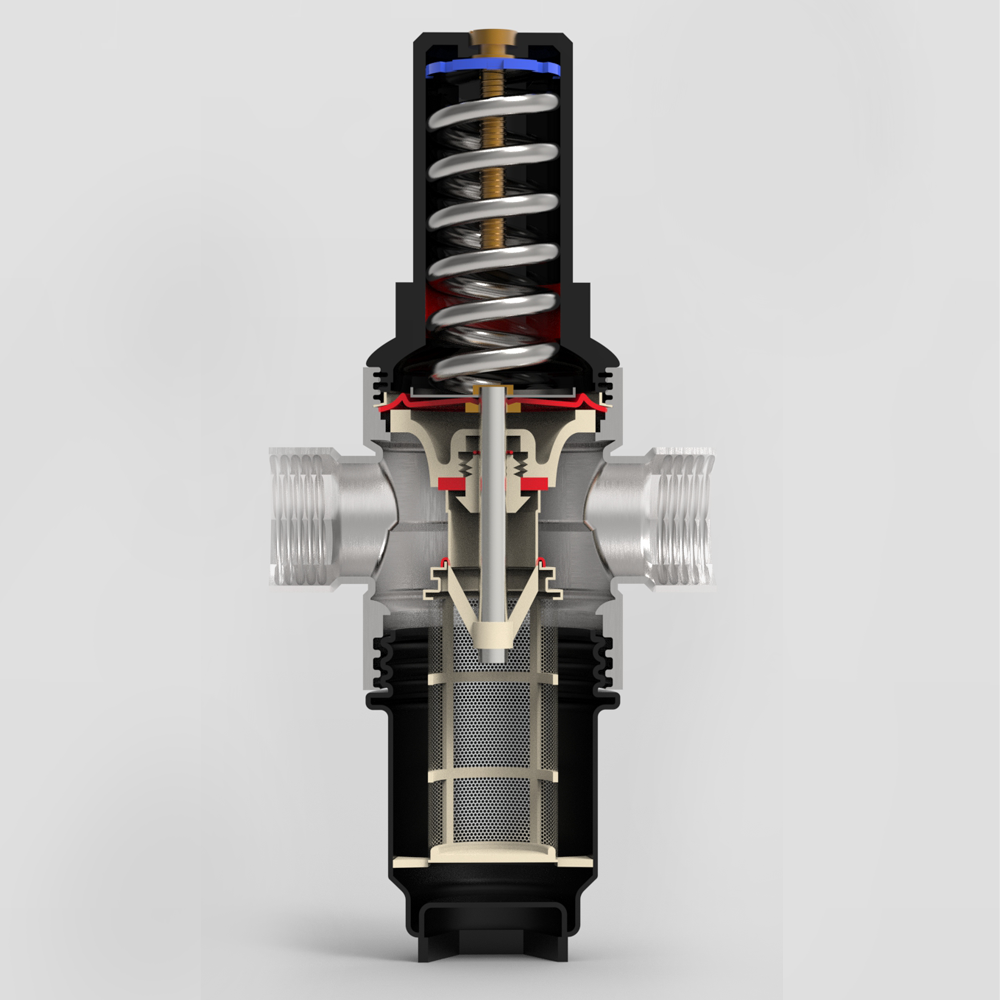

Pressure Reducing Valves of this type protect household water installations against excessive pressure from the supply. they can also be used for Industrial or Commercial applications within the range of their specification. By installing a pressure reducing valve, pressurization damage is avoided and water consumption is reduced. the set pressure is also maintained constant, even when there is wide inlet pressure fluctuation. reduction of the operating pressure and maintaining it at a constant level minimizes flow noise in the installation.

| Type | Diaphragm Spring Operated with In-Built Filter | ||||||

|---|---|---|---|---|---|---|---|

| PN Rating | 25 kg/cm2 | ||||||

| Warranty | 5 Years with *T&C Applied |

| Body Material | Stainless Steel |

|---|---|

| Spring Bonnet | Synthetic Material |

| SS Filter Mesh | 200 Micron |

| Pressure Set point Range | 1.5 kg/cm2 to 6 kg/cm2 |

| Spring | Spring Steel |

| Filter Cap (Max 16 kg/cm2 ) SS Filter Cap (Max 25 kg/cm2 ) | Black Synthetic Material to avoid forming of ALGAE due to Sunlight |

| Maximum Temprature | 65°C |

| End Connections | BSP Female Threaded |

Addtional Description

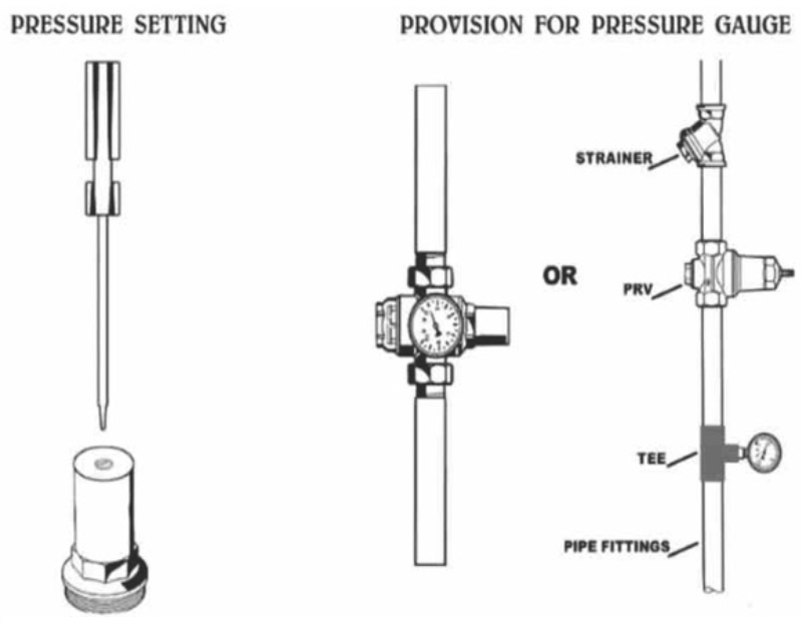

- The Outlet Pressure is Set by Turning The Adjustment Knob.

- The Adjustment Spring is Not in Contact with The Potable Water.

- The Valve Insert is of High Quality Synthetic Material and can be Fully Exchanged.

- Inlet Pressure Balancing - Fluctuating Inlet Pressure Does Not Influence Outlet Pressure.

- Light Weight due to Synthetic Material Internals.

- Horizontal & Vertical Installation Position Possible.

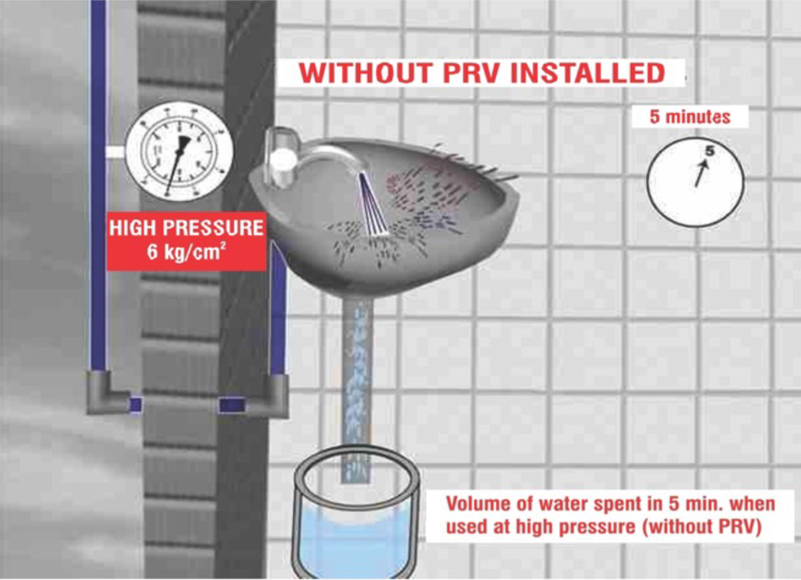

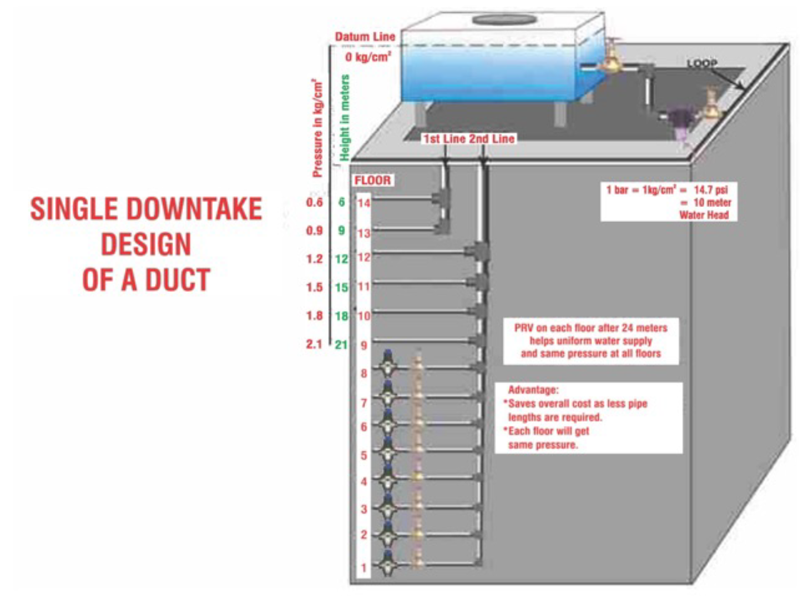

WHAT IS PRESSURE:- In High Rise Tower when water is released downward into the supply line from Over Head Tank (OHT), due to gravitational pull water gets accelerated resulting in increase of pressure on every downward floors. This means water pressure is lowest on the top floor and keeps increasing as and when water travels downwards towards ground floor. Hence, resulting highest water Pressure on the ground floor. Units used to measure pressure are kg/cm2, Bar & PSI. In India water Pressure is generally measured in kg/cm2 Where 01 kg/cm2 = 0.98 Bar = 14.7 PSI

HOW TO CALCULATE PRESSURE:-

1. Calculate Water Head (WH)

2. WH = No. of Floors x Height of each Floor + OHT Height (OHT Top to Terrace Flooring)

3. Divide WH by 10 and it will give you the answer in kg/cm2 For example, WH = No of Floors is 25 x Height of each floor is 3 meters + OHT Height is 5 meters WH is 25 x 3 + 5 = 80 meters further ÷ 10 = 8 kg/cm2 Hence in 25 storey tower pressure on the Ground Floor is 8 kg/cm2 as WH is 80 meters.

In simple words when water travels 10 meters (vertically only) it will develop Pressure of 01 kg/cm2 irrespective to Pipe size or Capacity of OHT. As per Hydraulic Law on every 10 meters of WH water supply line will develop 01 kg/cm2 Pressure.

Major issue faced by the Residents in High Rise Towers are like

1. Leakages from water pipelines / Health Faucet (Jet Spray) / Flush Valves

2. Bursting of Pipes / Geysers / Joints

Damaging Membrane in water Purifying Machine / internal delicate parts of Bathroom Fittings / Washing Machine

3. Certain hidden losses by reducing the Life of Water Appliances for e.g., life of a health faucet (jet spray) is 3 years but due to continuous high pressure its life gets reduced to 6 months or even less depending upon how high pressure is there in health faucet.

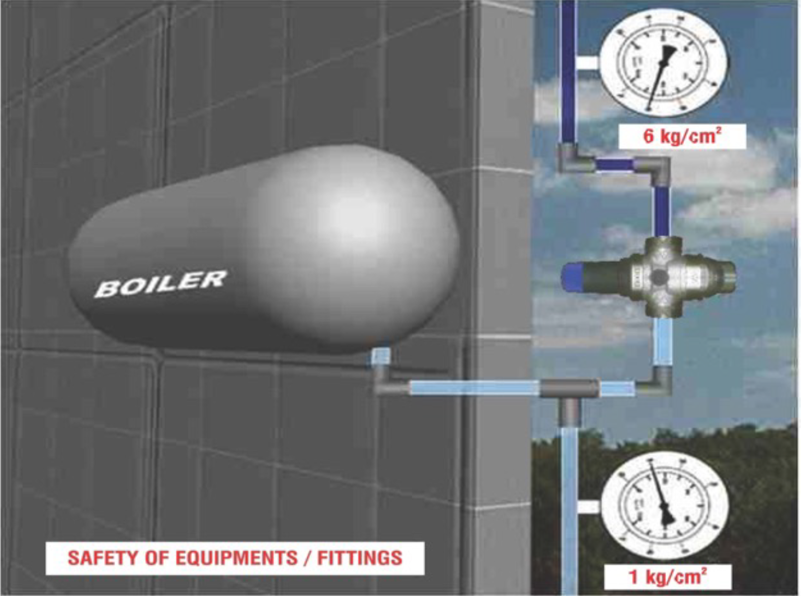

Slide 2 A

Before PRV

Slide 2 B

After PRV

When water Pressure is more than 1.5 kg/cm2 you are letting out more water every time you turn on a tap. All of that adds up in the long run & if the place has scarcity of water & have to pay for the water being used then this high pressure will end up costing more money to the end user. Hence for water conservation and to save the extra cost on water consumption PRV installation as shown in images becomes a necessity and also it will safe guard all your water appliances and water pipes from pressurized damages.

Slide 3 A

Before PRV

Slide 3 B

After PRV

As shown in images four different lines (header) are coming from terrace supplying water to 14 toilets.

PRV are installed in main line at the place where pressure is exceeding 2.4 kg/cm2 and reduces it to 1.5 kg/cm2, hence controlling pressure at all the four floors and preventing pressurized damages.

Advantage: Installing PRV in main supply line reduces the cost as only 2 No. of PRV’s are installed and all last 8 floors are controlled.

Disadvantage : Even after PRV installation all the floors will not have uniform pressure because as explained earlier the moment water travels downward it will increase pressure hence the bathroom/kitchen which is immediate after PRV installed will have less pressure and the last bathroom/kitchen from the PRV installed will have maximum & maintenance of PRV at times becomes impossible as access to PRV is only from that bathroom/kitchen where PRV is installed and if the access to the PRV is not available for some reason then PRV is not able to maintain and every toilets below will have to face problem.

Now as shown in the other image the PRV’s are installed in branches in last 8 Bathroom/kitchens hence No. of PRV’s is increased from 2 nos. to 8 nos.

Advantage: Every Bathroom/kitchen will have uniform Pressure and can adjust Pressure as per the individual requirement secondly PRV maintenance is always possible as access is from the same bathroom/kitchen where PRV requires maintenance.

Disadvantage: Total Cost of PRV increases by 50% – 75% as no. of PRV’s are more.

Slide 4 A

Slide 4 B

Why double PRV required

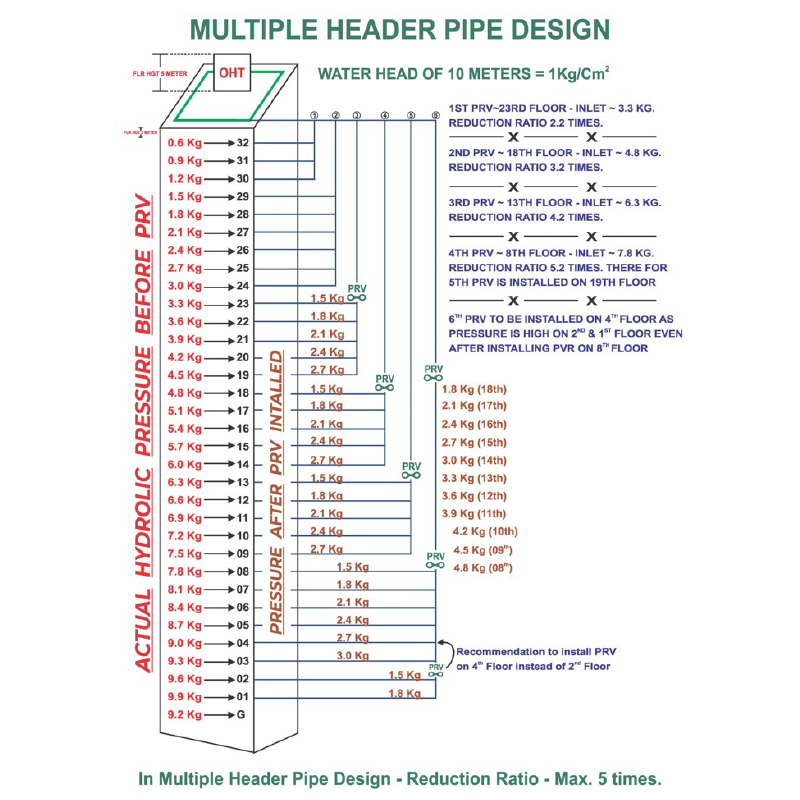

It is the e.g., of a 32 storey & 22 Storey apartments and both having a different schematic (pipe design of water distribution of entire apartment) Actual Hydraulic Pressure is very high in 32 storey which is 9.9 kg/cm2 on 1st Floor bathroom/kitchen due to which Three PRVs are installed in Header no.6 (supply line) supplying water from 8th floor. to 1st floor. (Zone) this is because inlet pressure in PRV installed on 8th floor. is 7.8 kg/cm2 which is out of Reduction Ratio (Inlet to outlet ratio) and so cannot be reduced directly to 1.5 kg/cm2 which is the minimum pressure required, so one more additional PRV had to be installed on 19th floor. so that the inlet pressure on 8th floor. PRV is reduced to 4.8 kg/cm2 as shown the increasing pressure from 19th floor. to 8th floor. which was otherwise 7.8 kg/cm2 without PRV installed on 19th floor.

One more PRV is also installed on 4th floor. inside the Zone. This is because PRV installed on 8th floor. with outlet pressure of 1.5 kg/cm2 gets increased again to 3.6 kg/cm2 by the time it reaches on 1st floor. which is high and needs to be reduced therefore one more PRV is installed on 4th floor.

Reduction Ratio in these particular schematics is 5 times which means if PRV outlet pressure is set at 1.5 kg/cm2 your inlet pressure should not increase 7.5 kg/cm2 (5 times i.e., 1.5 x 5 = 7.5).

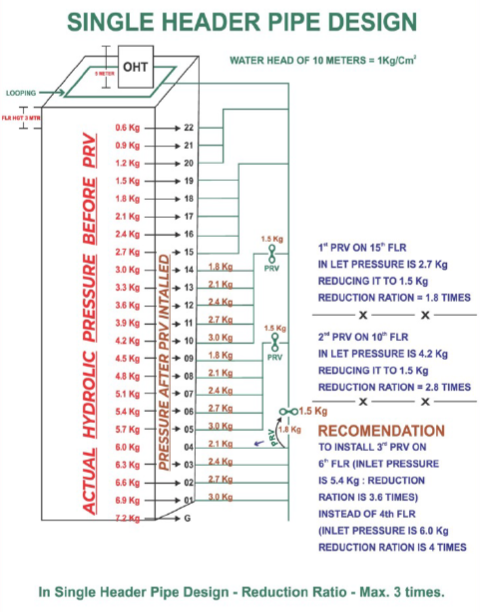

Whereas in 22 storey there is a single header coming from terrace distributing water to all the floors through 5 zones coming from that same single header as shown in slide 06. In this kind of pipe design Reduction Ratio is 4 times. As shown PRV is recommended to install on 6th flr instead of 4th flr this was done to save cost of additional PRV as you can see the actual hydraulic pressure on 6th flr is 6 kg/cm2 which is on the border of 4 times Reduction Ratio and as there are only four floors in the last zone there is an possibility and buffer to install PRV two floors above so that it comes under the Reduction Ratio limit as inlet pressure on 6th flr.is 5.4 kg/cm2 within the limit of 4 times reduction Ratio (1.5 x 4 = 6).

NOTE : REDUCTION RATIO IS BETWEEN 3 TIMES TO 5 TIMES, DEPENDING UPON PIPE DESIGN.

Slide 5A

Slide 5B

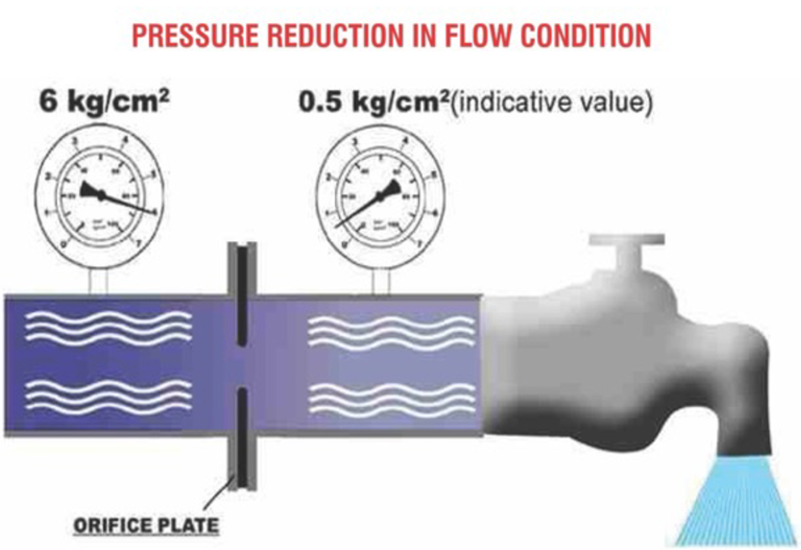

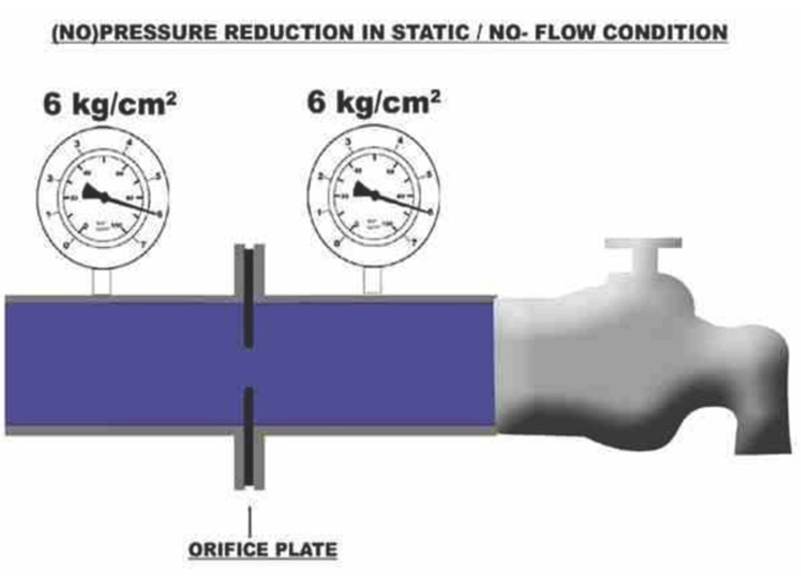

Before PRV came into existence Orifice plate was being used to reduce pressure. Orifice plate is a device which reduces the flow rate of the water, it’s a thin plate with a hole from which the water passes through resulting to reduction in water pressure due to reduction in flow rate and so these Orifice plates were installed at areas were pressure is high and needs to be reduced.

Slide 7A

Slide 7B

Slide 7C

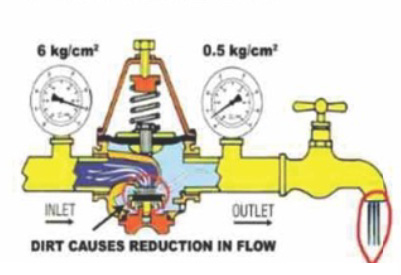

As shown in Slide 7A Orifice Plate is installed at the point were Pressure is 6 kg/cm2 pressure at its outlet is reduced to 0.5 kg/cm2 these reduction was noticed when Tap which you can see is completely kept open because as shown in slide 7B were the tap is kept half open the pressure on the outlet of Orifice Plate shoots up to 3 kg/cm2 and in the last image 7C were the tap is kept completely closed the outlet Pressure is the same of Inlet Pressure of Orifice Plate i.e 6 kg/cm2 This proves that Pressure Reduction is happening only in Dynamic condition (flow condition) i.e. when tap is open were as in Static condition (no flow) i.e tap kept close there is no Pressure Reduction.

Hydraulic Law which states that Pressure will transmit from Inlet to Outlet in Static condition from any Device even if there is a Hair Line Gap left within the device allowing water to flow further. Due to this above reason Orifice Plate is no more in use as it does not solve the purpose of reduction in water pressure in Static condition. It is noticed that at a few of the sites people throttle the Ball valve which are installed on the terrace just before the down takes (supply line) and reduce the flow of water thinking it will reduce the pressure but as explained in static condition the pressure transmits and pipe bursting is heard especially at night when water line is completely pressurized due to zero flow.

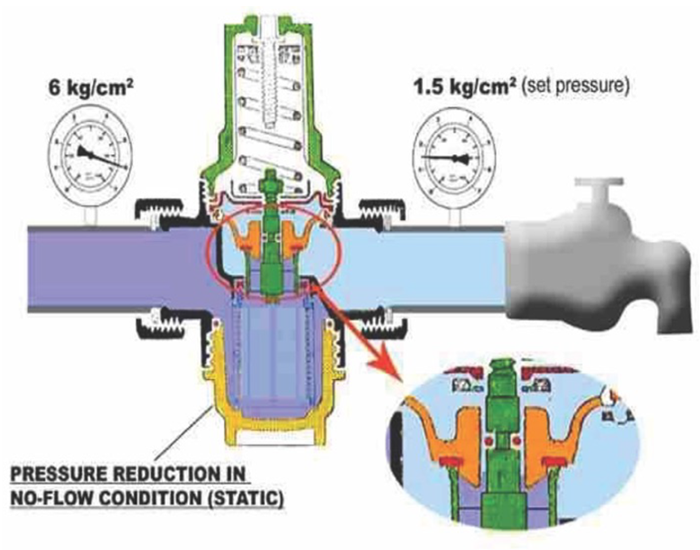

Slide 8A

Slide 8B

Pressure Reducing Valves, commonly known as PRV is an self acting automatic control valve, without the necessity of an external power source. In simple words it’s a valve which gets opened when tap is open as shown in slide 8A and closes automatically when tap is close as shown in slide 8B, hence reciprocating with the requirement of water. Opening of valve means getting desired outlet pressure set (1.5 kg/cm 2 to 6 kg/cm 2) without affecting much the Flow Rate. Closing of valve means shutting off the valve completely not even leaving a hair line gap or allowing a single drop of water to flow further and controlling high Inlet Pressure to set outlet pressure which is generally set at 1.5 kg/cm 2.

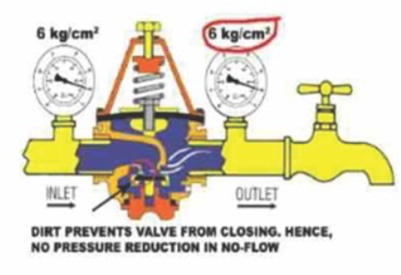

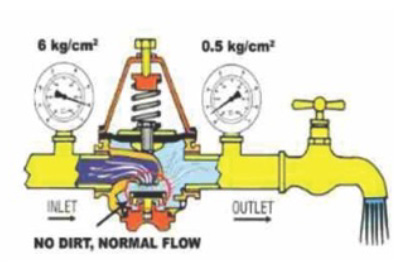

WHY PRV FAILS

Slide 9A

Slide 9B

Slide 9C

Slide 9D

As shown in slide 9A Inlet pressure of 6 kg/cm2 has been reduced to set outlet pressure of 1.5 kg/cm2 in Static condition as you can see the tap is closed showing PRV is functioning properly, but in slide 9B the outlet pressure has shoot up in Static condition to same of Inlet i.e. 6 kg/cm2 which indicates that PRV is not functioning. The reason is as you can see there are some solid particles accumulated at opening & closing area obstructing the PRV to close completely allowing water to flow further through that gap as shown in the figure with those white lines showing flow of water. As explained earlier Pressure Transmits in Static Condition and so this PRV installed is not working resulting to Pressurized damage to all water appliances installed in Bathroom/kitchen, Pipe Bursting especially the joints and leakages in Concealed Pipes, secondly these solid particles also restricts the flow rate of water, as shown in slide 9D the discharge of water from the tap has reduced to half as there are some solid particles obstructing the flow area as compared to the tap shown in slide 9C where there is no solid particle obstructing the flow area and the discharge of water from the tap is also better.

NOTE : PRV are generally installed in main line which supplies water to 5 to 6 Bathroom/kitchens hence Pressurized damages are seen in all those Bathroom/kitchens, so right kind of PRV installation becomes a necessity which Safe Guards Water Appliances / Protects Pipes bursting and also maintains required Flow Rate with Desired Pressure.

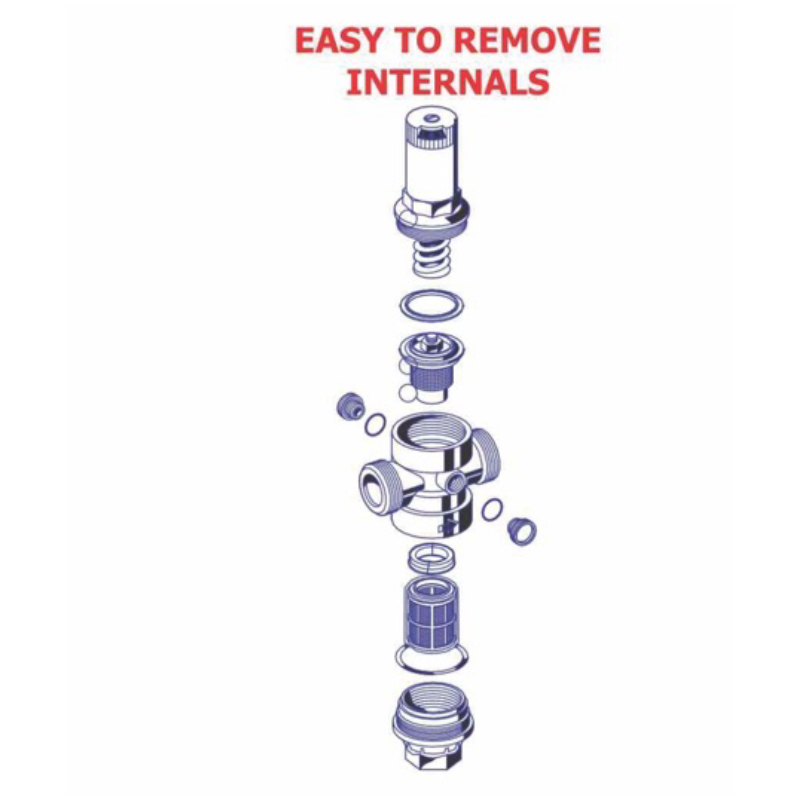

Sana’s PRV with In-Built Filter

As shown in slide 10 and explained earlier for slide 9A Inlet pressure of 6 kg/cm2 has been reduced to set outlet pressure of 1.5 kg/cm2 in Static condition as tap is closed, showing PRV has reduced the High Inlet Pressure to 1.5 kg/cm2 and is functioning properly by not allowing Inlet to Outlet Pressure Transmit. The major reason for this to happen is the In Built Filter which is given below the actual mechanism of the PRV as shown in the fig.Trapping all the Solid Particles up to 200 micron (0.2mm) not allowing to flow further inside the mechanism ensuring PRV working 24×7 with desired Set Pressure and without hampering the flow rate.

NOTE : These In-Built Filter is Openable and can be cleaned in few seconds.

Slide 10A

Sana’s PRV with Light Weight Internals

By now you have understood that the main mechanism in a PRV is of Opening and Closing Reciprocating to demand of water. In peak hours there is a continuous fluctuating demand of water due to which PRV at times has to move in reverse direction meaning instead of closing it has to remain open due to sudden demand, in this case PRV starts vibrating and startsmaking howling sound. These issue is majorly found in Piston operated PRV’s were the Internals are made of heavy metals like Brass, making PRV’s mechanism very slow and sluggish.

To eliminate this issue Sana’s PRV comes with Light Weight Internals which are non corrosive & Food Grade Synthetic Material (German make Engineering Plastic) which can with stand pressure up to 25 kg/cm2 , these Light Weight Internals reciprocates faster to the demand of water hence when it has to move in reverse direction, the PRV does not vibrate or create any howling sound making it the most Silent and noice less PRV available, secondly it also makes the over all PRV very light and due to which no support (bracket) is required in installing PRV especially in these Plastic CPVC & UPVC Pipes, were as Piston operated PRV’s are very Heavy & Bulky due to brass internals and hence requires a special support to install them which is adding extra cost and also occupies extra place inside the duck area which are already very congested.

Slide 10B

Slide 10C

Slide 10D

Sana’s PRV with Corrugated Shape Diaphragm

Diaphragm in any kind of PRV is the part which divides PRV intotwo Chambers. 1st part is the Wet Chamber in which the water flows through the mechanism and part 2nd is the Dry Chamber which has Spring Fitted in it which Controls the Mechanism of PRV through these Diaphragm, hence making Diaphragm, the most important part of PRV, as it has to move Upward & Downward continuously in peak hours to Open & Close the PRV, Sana’s PRV Diaphragm are Thin & Corrugated shape as shown in slide 10C which helps the movement faster and also due to these movements there will be no kind of cracks unlike Piston Operated PRV’s, were the Diaphragm as shown in slide 10D which are very thick and are of almost Flat shape due to which in upward & downward movement these Diaphragm will start forming cracks and later will have to get it replaced very frequently as compared to Sana’s PRV Diaphragm.

NOTE : Sana’s PRV Diaphragm are thin but comes with a extra Nylon Grip attached on one of the sides making it more

Stronger and has a Longer Life than any other Diaphragm.

Sana’s PRV is the most Compact PRV with Minimum Flow Rate Loss

Diaphragm in any kind of PRV is the part which divides PRV intotwo Chambers. 1st part is the Wet Chamber in which the water flows through the mechanism and part 2nd is the Dry Chamber which has Spring Fitted in it which Controls the Mechanism of PRV through these Diaphragm, hence making Diaphragm, the most important part of PRV, as it has to move Upward & Downward continuously in peak hours to Open & Close the PRV, Sana’s PRV Diaphragm are Thin & Corrugated shape as shown in slide 10C which helps the movement faster and also due to these movements there will be no kind of cracks unlike Piston Operated PRV’s, were the Diaphragm as shown in slide 10D which are very thick and are of almost Flat shape due to which in upward & downward movement these Diaphragm will start forming cracks and later will have to get it replaced very frequently as compared to Sana’s PRV Diaphragm.

NOTE : Sana’s PRV Diaphragm are thin but comes with a extra Nylon Grip attached on one of the sides making it more

Stronger and has a Longer Life than any other Diaphragm.

Slide 10E

Sana’s PRV are Life Long

Sana’s PRV comes with Dual Opening and all 26 different parts which are assembled inside the PRV are removable as shown in slide 17 and can be cleaned / Replaced and Maintained Easily in Few Seconds whenever required unlike other Piston operated are not openable AT ALL due to which PRV cannot be maintained AT ALL. In areas were there is HARD WATER in use, forms Calcium Deposits known as Scaling Inside the PRV which later disturbs PRV’s inside Mechanism affecting Flow Rate and also the Performance hence in such cases Sana’s PRV are the only option left as these Dual opening Features of Sana’s PRV is not available in other makes, and if available, they are not in SS body. Sana’s PRV comes in SS-304 grade Body and its Life is almost more than 50 Years and once fitted in between the Pipes are FITTED FOR EVER and no such requirement in Future will ever come were there is a need to remove the PRV for Maintenance because as explained Every Part Inside is removable making PRV body hollow and is even able to clean the body from inside. Hence Sana’s PRV are Life Long because up to 5 years of Warranty any part, when required is replaced free of cost and in future after warranty when the building is going under Restoration, just by replacing all the internals of PRV will make PRV as good as New as SS body never gets affected and never requires to be replaced making Sana’s PRV Life Long.Sana’s PRV is occupying much lesser space in the Duck Area as compared to Piston operated and now these has become a very important Aspect as duck sizes are going smaller and more congested due to lot of Pipes for different purpose are also passing inside these Duck.

Sana’s PRV is occupying much lesser space in the Duck Area as compared to Piston operated and now these has become a very important Aspect as duck sizes are going smaller and more congested due to lot of Pipes for different purpose are also passing inside these Duck.

Slide 10F

Sana’s PRV Comes in SS making it Lead Free

- * Brass contains Lead which is Toxic to Small Children below 8 years of age. SS-304 does not have Lead and is Environment Friendly.

- * Brass contains Zinc which under goes a process called Dezincification were the Zinc portion gets Evaporated into the Atmosphere after few years depending upon the humidity (5 to 10 years), leaving Copper behind and resulting holes in the body and ultimately requires new valve. Were as the SS-304 body does not get effected from any climatic conditions and its Lifespan is almost 50 years and even more, so the problem of valve replacement never comes.

- * Installed Brass Body Valve can get Stolen from the Site as resale value of Brass is high were as resale value of SS is very less.

- * Brass is a soft metal and less durable and SS-304 is the Strongest Alloy so it’s a better option to withstand high pressure / high temperature & effectively resisting leaks through cracks from the body.

- * Brass is able to withstand corrosion, however SS-304 is still the best in corrosion, especially in Marine Environment.

Slide 10G

Sana’s PRV are with In-Built Provision for Pressure Gauge

Slide 10H

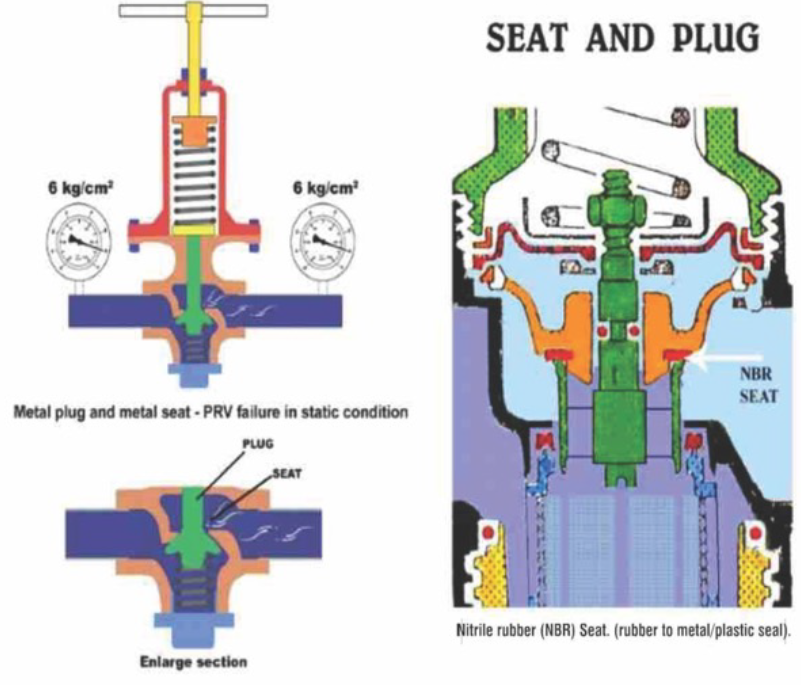

Sana’s PRV with Rubber Seat

Seat is a part which is placed on the upper side of the opening & closing area of PRV. Its function is to help PRV in Shutting off completely restricting water to flow further. In Sana’s PRV these Seat is made of Rubber which is soft in Nature and are food grade and on the lower side there is a part called Plug made of engineering plastic has sharp edge which collides and penetrates into this soft rubber Seat placed above helping PRV to Shut off completely and not allowing water to flow further. These Seats is working like a gasket which prevents leakages as shown in the figure XXX.

Were as in other Piston Operated PRV these seats are made of metal and even the plug which collides into these seat is made of metal, hence Metal to Metal as shown in fig. xxx leaves some hair line gap resulting to minor leakages ultimately transmitting Pressure of In-let to Out-let and this is one of the reason why Piston Operated PRV fails.

NOTE : Due to Technical Limitations all these Piston Operated cannot have those Important Features which Sana PRV has especially In-built Filter & Rubber Seat.

Slide 10I

FARMEY SERVICES

The Precision For Agriculture

Customized advice to smallholder farmers with radical efficiency and scalability agricultural methods used. Curabitur mollis bibendum luctus.

Natural Wheats

Grass widely cultivated for its seed, a cereal grain which is a worldwide praesentium voluptatum.

Fresh Vegetables

Formulate and direct the agricultural policy of the country as a whole, in accordance general.

Fresh Fruits

Study the economic and social aspects the production, distribution and consumption products.

Healty Cattle

Preserve renewable natural resources, regulate their use, increase them and promote their rational.

Modern Truck

Approve and supervise agricultural vocational school programs provide assistance and formulate.

Farm Plans

The export and import substitution possibilities agricultural products and formulate policy.

WHAT OUR CLIENTS SAYS

My testimonial is from a customer or client. They may be an unknown person to the reader, you need to be sure there isn't anything embarrassing hidden in the middle of text. An endorsement influencer giving their public support.

Richard Johnson

Marketing

Weakness of will, which is the same as saying through shrinking from toil and pain. These cases are perfectly simple and easy to distinguish have suffered alteration in some form, by injected humour or randomisation.

Maria Todd

Food Collector

Pleasures have to be repudiated and annoyances accepted. The wise man therefore always holds in these matters to this principle of selection influencer giving their public support for a brand. But a testimonial is from a customer or client.

Alex Cora

Farmer

KEEP IN TOUCH

We will be the leading company in the national market with each of our products.

info@sh112.global.temp.domains

Write us an email for your requirements & queries

+91 98206 94542

Connect with us now Lets find a solution together

KEEP IN TOUCH

We will be the leading company in the national market with each of our products.

info@sanasaquagreengmail.com

Contact us if you have a question

+91 98206 94542

Send us an email to keep in touch